What is quartz?

Quartz is a mineral composed of silicon dioxide. Its physical and chemical properties are very stable. It is also one of the most common minerals on earth. In a broad sense, quartz also includes high-temperature quartz and coesite. The main component is silicon dioxide. It is colorless and transparent. Because it contains a small amount of impurities, it becomes translucent or opaque crystals with a hard texture.

How is quartz formed?

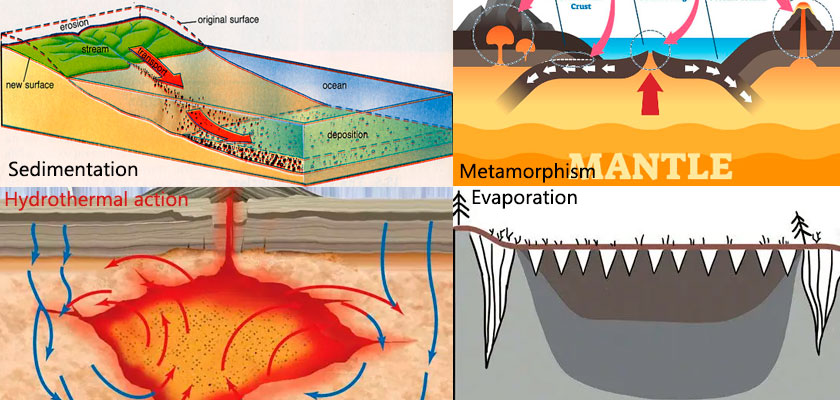

Magma cooling: When magma cools, silica-rich crystals form quartz.

Hydrothermal activity: Hydrothermal fluids carry silica and precipitate in cracks to form quartz crystals.

Metamorphism: Under high temperature and high pressure conditions, minerals in the original rock recrystallize to form quartz.

Sedimentation: In rivers, lakes and marine environments, quartz particles are deposited to form quartz sand, which is further consolidated to form sandstone.

Biological action: The shells of diatoms and radiolarians are composed of silicon dioxide. After death, their shells are deposited on the seabed and siliceous rocks are formed through diagenesis.

Volcanic activity: When a volcano erupts, the lava cools quickly to form volcanic glass. Over time, the volcanic glass can devitrify to form microcrystalline quartz.

Quartz crystal

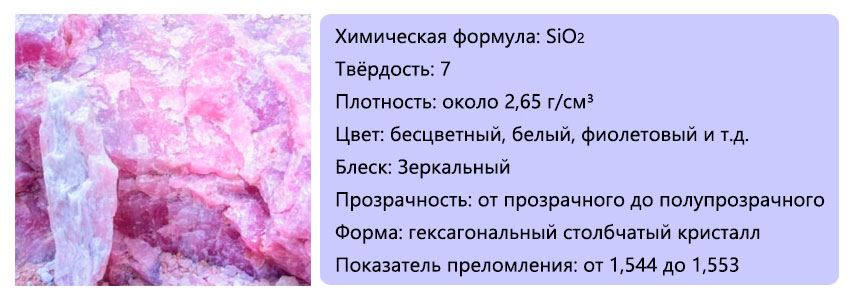

The structure of quartz crystal is a silicon dioxide crystal composed of silicon and oxygen atoms, with a highly ordered atomic structure.

The quartz crystal structure belongs to the trigonal crystal system, and hexagonal columnar crystals are common, with horizontal stripes on the column surface and rhombohedral ends.

There is a spiral axis in the quartz crystal structure, and the silicon oxygen tetrahedron is arranged along the spiral axis to form a left-handed or right-handed spiral structure. This spiral structure causes quartz to have optical activity.

Quartz crystal has optical activity and can rotate the vibration direction of polarized light.

Quartz crystal has birefringence, and the light enters the crystal and is divided into two beams with different propagation speeds.

Characteristics of quartz

Physical properties: Quartz is usually colorless or white, but it may also appear purple, pink, yellow, gray, etc. due to impurities. Quartz is hard, with a hardness of 7, a glassy luster, and an oily luster on the fracture. Common hexagonal columnar crystals, with horizontal stripes on the column surface and often rhombohedral shapes at the ends.

Optical properties: Quartz crystals have optical rotation, good transmittance to ultraviolet light, and birefringence.

Electrical properties: Quartz crystals have piezoelectric effect and good dielectric properties.

Chemical properties: Quartz is insoluble in water and most acids at room temperature, has high chemical stability, and is not easily corroded.

Mechanical properties: Quartz is a brittle material that is easy to break when impacted by external forces, but has high wear resistance.

What is the use of quartz?

Electronic industry: The piezoelectric effect of quartz crystals makes it an ideal material for manufacturing high-precision oscillators and filters, and is widely used in clocks, communication equipment, computers, and smart phones.

Optical instruments: The high transparency and heat resistance of quartz make it suitable for manufacturing optical lenses and prisms. In addition, quartz has good transmittance to ultraviolet light and is often used in ultraviolet spectrometers and other ultraviolet optical equipment.

Jewelry and decorations: Quartz crystals are colorless and transparent, and are often used to make jewelry and decorations.

Glass ceramics: Due to its high hardness, quartz is often used as an abrasive to make grinding wheels, grinding materials, polishing materials, etc. Quartz is used to make refractory bricks and other refractory materials, and is widely used in metallurgy and glass industries. Quartz is used in ceramic bodies and glazes to improve the strength and heat resistance of ceramics.

Chemical industry: Quartz is a raw material for making various silicon compounds, which are used to make detergents, adhesives and catalysts.

Construction industry: Quartz sand is used to make concrete, mortar and building sand. Artificial quartz stone is used for kitchen countertops, floors and wall decoration.

Art and carving: Quartz crystals are often used in artistic carving and handicrafts because of their beauty and hardness.

Water treatment: Quartz sand is used as a filter medium in water treatment to remove suspended matter and impurities in water.

Medical industry: The stability and purity of quartz also make it used in some medical instruments, such as some precision medical sensors, detection instruments, etc.

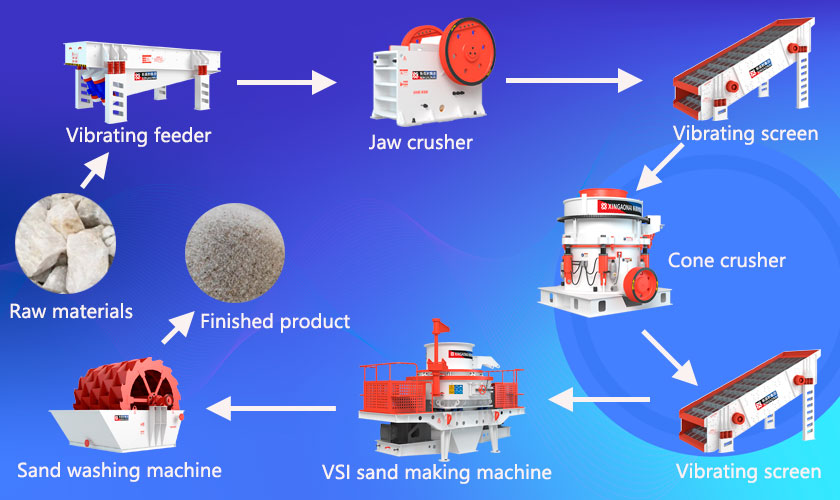

Quartz sand production process

Main equipment and process: large stones enter the warehouse → coarse crushing (jaw crusher) → fine crushing (cone crusher) → sand screening (impact sand making machine + vibrating screen) → sand washing machine (cleaning and removing impurities, producing finished sand) → conveyor;

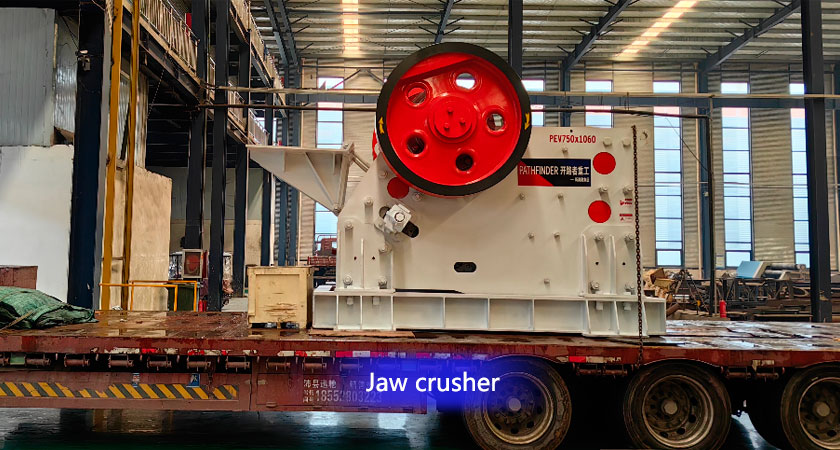

Advantages of jaw crusher

The jaw crusher has become an indispensable primary crushing equipment in industries such as mining and construction with its simple structure, convenient maintenance, efficient crushing, wide application range, high reliability, energy saving and environmental protection, simple operation, low investment cost, strong adaptability and high safety performance.

Advantages of cone crusher

The cone crusher has become an indispensable medium and fine crushing equipment in industries such as mining and construction with its efficient crushing, large production capacity, wide application range, high reliability, energy saving and environmental protection, simple operation, convenient maintenance, strong adaptability, high safety performance, advanced technology and high return on investment.

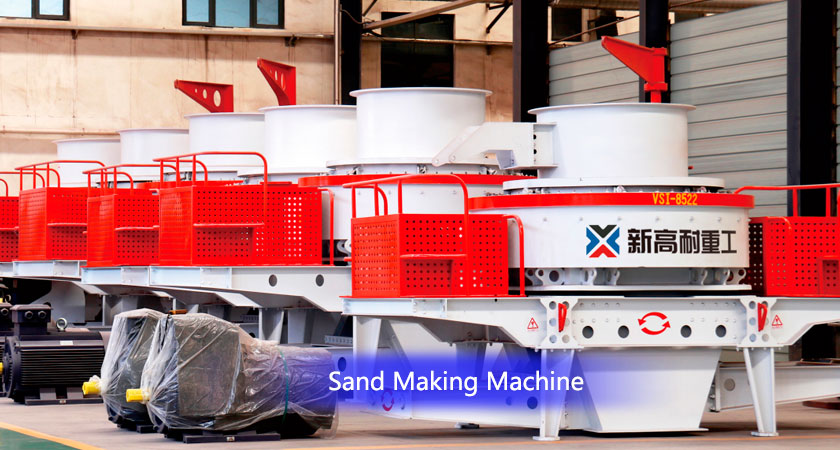

Advantages of VSI sand making machine

VSI sand making machine has become an indispensable and efficient sand making equipment in industries such as construction and mining with its advantages of high efficiency sand making, versatility, energy saving and environmental protection, simple operation, convenient maintenance, strong adaptability, high safety performance, advanced technology, high return on investment, good sand shape and low operating cost.

How much does it cost to build a quartz sand plant?

There are high and low prices on the market, usually ranging from 30,000 to 150,000 US dollars. Because there are many manufacturers now, the price difference is very large. Moreover, according to the different models, output and equipment configuration, it can also vary a lot. Among them, Henan Xingaonai Factory has undergone 30 years of innovation and development, with standardized equipment and factory buildings, large scale, fast production speed, complete quartz sand processing equipment, and any choice. They are all sold directly from spot. For specific price information and more relevant information, there are technical managers to answer your questions.

Article Title: What is Quartz? What is Quartz used for?

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/what-is-quartz-what-is-quartz-used-for.html